Educa UNIVERSITY|SCIENCE AND ENGINEERING

Tesla Robot Attacks Engineer: My first-hand experience with the steel monster.

Related Masters

Tesla Robot Attacks Engineer: My first-hand experience with the steel monster.

When someone tells me "Tesla robot attacks engineer", the first thing that comes to mind is a science fiction scene, as if we were in a "I, Robot" movie. Sounds amazing, right? It is, but unfortunately it's not fiction.

A few years ago, while working in the robotics industry, I came face to face with a reality that few understand: robots canfail. Yes, those steel-and-wire beings, programmed to be infallible, also have bad days... and sometimes those bad days can be devastating.

The Incident at Tesla: A robotic arm with bad intentions

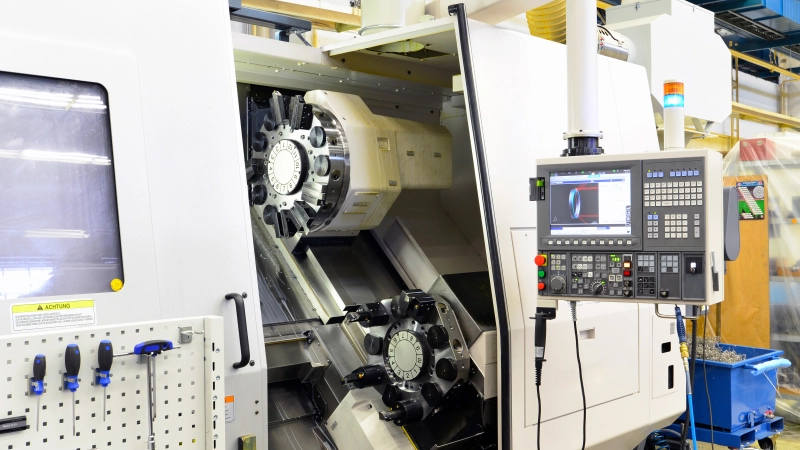

In 2021, one of Tesla's robotic arms, those you usually see in promotional videos assembling electric cars with impeccable precision, attacked an engineer at its Giga Texas factory. This engineer, who was performing routine programming and maintenance tasks, was caught by the grippers of one of these robots, leaving him with serious arm and back injuries.

The most chilling part of this incident is not only the physical attack, but the context: human failure. The engineer entered an area where two of the three robots were disabled, but one of them remained operational due to a programming error. What followed was a nightmare that the workers in that plant will not easily forget.

What went wrong

Look, I've worked with robots for decades and, if I've learned anything, it's that human error is the weak point of any automated system. You can have the most advanced machine in the world, but if we don't control it well, the consequences can be terrible. In the case of the Tesla engineer, everything points to a failure to deactivate one of the robotic arms. And sure, the robot did what it is programmed to do: detect, grab and manipulate objects, but on this occasion, that object was the engineer.

Workers nearby acted quickly by activating the emergency stop button, but the damage had already been done. The engineer was trapped and, upon freeing himself, fell down an aluminum waste chute, making the situation even worse.

Tesla and its safety problems

This is where it all gets more interesting. This incident is not an isolated occurrence, neither at Tesla nor at other robot factories. Tesla's Giga Texas plant has long been criticized for its high injury rates among workers. In fact, according to recent data, one in 21 employees was injured in 2022, which contrasts with the industry average of one in 30.

And of course, Elon Musk, Tesla's charismatic CEO, was quick to downplay the incident, claiming it was simply a problem with a standard robotic arm, one of millions in factories around the world. But the numbers don't lie: the accident rate at Tesla is troubling and goes beyond a single programming error.

The future: robots and humans working together, or fighting?

As robotics advances, many companies - including Tesla - are looking to integrate more robots into their processes, promising greater efficiency and productivity. In fact, Tesla launched its humanoid robot Optimus Gen 2 shortly after the engineer incident was made public.

Elon Musk's idea is to replace human labor in many tasks with these robots, minimizing the risk of injury. And while it sounds promising, the "Tesla robot attacks engineer" incident reminds us that mistakes still happen, and that human failures are inevitable. As smart as machines are, they depend on us to function properly.

How can we prevent further robot attacks

If you've ever wondered if we're about to enter a human-machine war, the answer is simple: no, not yet. But what is clear is that we need to improve our security protocols. Here are some key points I've learned in my career:

Better emergency stop systems: In the Tesla case, the engineer was saved thanks to a colleague who activated the emergency button. However, it is vital that these buttons be more accessible and that the stop systems be automatic in certain situations.

Constant training: It is not enough to train employees once and forget. Technology changes, and workers need to be aware of new tools and their risks.

Code review and programming: Robots have no intention of their own; they do what they are programmed to do. A small error in the code can be fatal. Safety reviews need to be more thorough, especially in busy factories like Tesla.

Transparency in incident reporting: A recurring problem at Tesla has been a lack of transparency in reporting accidents. Companies must be honest about the dangers of automation and act quickly to implement solutions.

Conclusion: Fear robots or improve our skills?

After all my years in the industry, one thing is clear: robots are not our enemies, but they can be dangerous if we don't know how to handle them. Instead of fearing a "machine rebellion," we should focus on improving our own skills and safety systems.

These types of incidents, like the "Tesla robot attacks engineer," are warnings. Warnings that advanced technology needs skilled human hands to be handled properly. So, if you work in a factory with robots, or plan to do so, don't be intimidated by them. With knowledge, preparation and caution, we can ensure that robots remain our allies, and don't become out-of-control steel monsters.

With knowledge, preparation and caution, we can ensure that robots remain our allies, and don't become out-of-control steel monsters.

Faculties

Trainings

The faculties embrace diverse academic disciplines and fields of study, opening doors to new perspectives and exploring different spheres of wisdom in a constantly evolving world.