Educa UNIVERSITY|BUSINESS

Laboratory Analysis and Quality Control: A Personal and Professional Experience

Related Masters

Laboratory Analysis and Quality Control: A Personal and Professional Experience

Hello! I'm Pablo García, and today I'm here to talk to you about a subject that has accompanied me throughout my career: the analysis and quality control laboratory. If you have come this far, you are probably interested in learning more about this fascinating world. And let me tell you something, you won't regret it.

I'm going to explain what an analytical and quality control laboratory is, how it works, and why it's so important. All this from a very personal perspective, because I've had the good fortune (and sometimes misfortune) of dealing with these labs in different industries. So, hold on tight because let's dive into this topic with depth and, above all, realism.

What is a Quality Control and Analysis Laboratory?

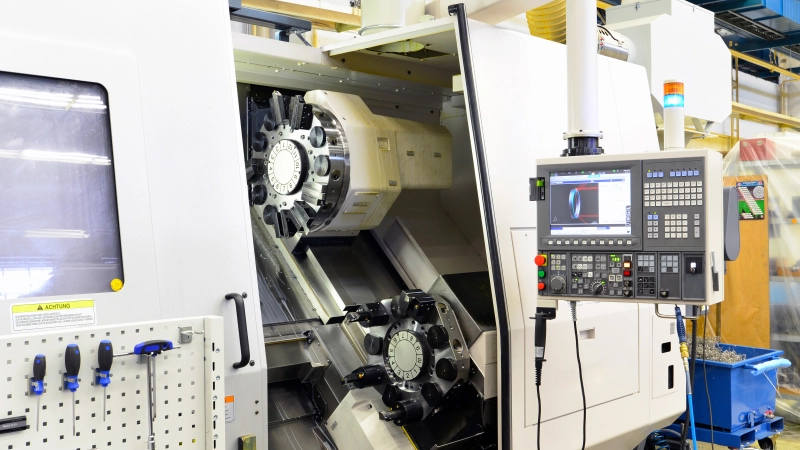

Imagine a place where every detail counts, where a small mistake can mean the difference between a quality product and an outright failure. That is, in essence, a quality control and analysis laboratory. These labs are at the heart of many industries: from food and pharmaceutical, to automotive and technology.

In such a lab, all kinds of tests and analyses are performed to ensure that products meet quality standards. This includes physical, chemical and even microbiological tests. The goal? To ensure that every product that goes to market is safe, reliable and meets all legal and quality specifications.

For example, in the food industry, an analysis and quality control laboratory is responsible for verifying that food does not contain microorganisms that could be harmful to health. In the pharmaceutical industry, it makes sure that each drug has the exact composition promised on its label. And in the automotive industry, it checks materials and components to ensure that each vehicle complies with safety regulations.

The Importance of Quality Control in a Laboratory

Now, you may be wondering, why is this quality control so important? I'll tell you in two words: safety and confidence. Good quality control in a laboratory is essential to prevent defective products from reaching the market. Imagine what a disaster a poorly formulated drug would be, or a car with defective parts. The consequences can be catastrophic.

Also, in an increasingly regulated world, meeting quality standards is mandatory. Regulations are getting stricter, and companies that do not comply face fines, product recalls and enormous damage to their reputation.

But it's not all negative. A good quality control system also offers opportunities. How? By allowing continuous improvement. Through the analysis of quality control results, companies can identify areas where to improve their processes and products, giving them a competitive advantage.

Equipment and Conditions in a Quality Lab

A quality control lab is not simply a room with some microscopes and flasks of chemicals. No, my friend, it is much more than that.

First, there is the specialized equipment. Here we talk about spectrophotometers, chromatographs, precision balances and many other devices that, if you see them, you probably won't even know what they are for (relax, it happened to me the first time too). This equipment must be in perfect condition, calibrated regularly to ensure that the results are accurate and reliable.

Then there are the environmental conditions. You can't perform accurate analyses if the temperature and humidity are not controlled. Labs have climate control systems that ensure everything is kept at optimal levels, so samples are not altered and results are consistent.

And I can't forget safety. This is key. A quality laboratory must have rigorous safety systems in place, from fire alarms to fume extraction systems. Working in a laboratory can be dangerous, and it is vital that all procedures are designed to protect both personnel, samples and equipment.

The Quality Control Process: Step by Step

Let's now talk about the quality control process itself. What happens when a sample enters the laboratory?

Sampling: It all starts with sample selection. Here it is crucial that the sample is representative of the batch to be analyzed. If the sample is not adequate, the results will not be adequate either.

Sample Preparation: Once selected, the sample is prepared for analysis. This may include dilution processes, extraction, or any treatment necessary for it to be properly analyzed.

Analysis: This is where specialized equipment comes into play. The necessary analyses are performed depending on the type of sample and what you want to verify. This can include techniques such as chromatography to separate components, or spectroscopy to analyze chemical composition.

Interpretation of Results: Once the analysis has been performed, the results are compared to predefined quality standards. If everything is in order, the sample passes quality control. If not, it's time to check what went wrong.

Report and Corrective Actions: Finally, a detailed report is generated with the results and, if necessary, corrective actions are implemented to correct any detected deviations.

Real Cases: What Experience Has Taught Me

I'm going to tell you something that not many people know. When I started in this world, I was working in a laboratory of a pharmaceutical company. One day, one of the products we were analyzing failed quality control. It was a minimal, almost imperceptible error. But in this business, almost is not enough. After investigating, we discovered that the problem was in a batch of reagents that had arrived improperly calibrated. If we hadn't caught that in time, there could have been severe consequences for patients consuming that drug.

That taught me the importance of being demanding at every stage of the process. There is no room for error when it comes to people's safety and health.

The Future of Quality Laboratories

The world of analytical and quality control laboratories is constantly evolving. With the advent of new technologies, such as artificial intelligence and automation, processes are being revolutionized. The laboratories of the future will be faster, more precise and efficient, but that does not mean that human labor will disappear. On the contrary, highly qualified professionals will be needed to manage and supervise these new technologies.

Faculties

Trainings

The faculties embrace diverse academic disciplines and fields of study, opening doors to new perspectives and exploring different spheres of wisdom in a constantly evolving world.